Oil-free water lubrication screw compressor

Classification:

Key words:

- Product Description

-

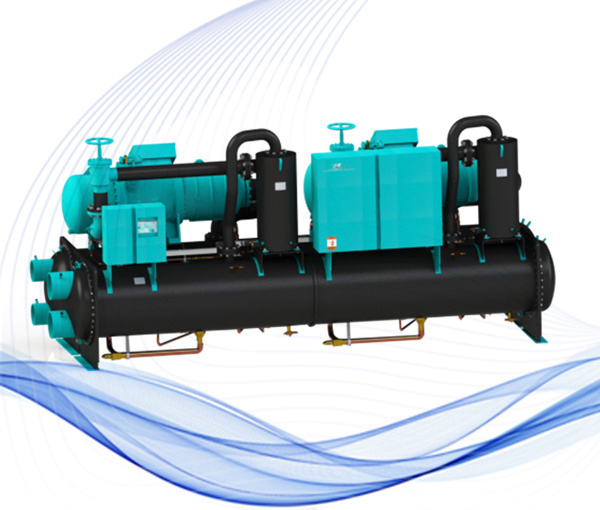

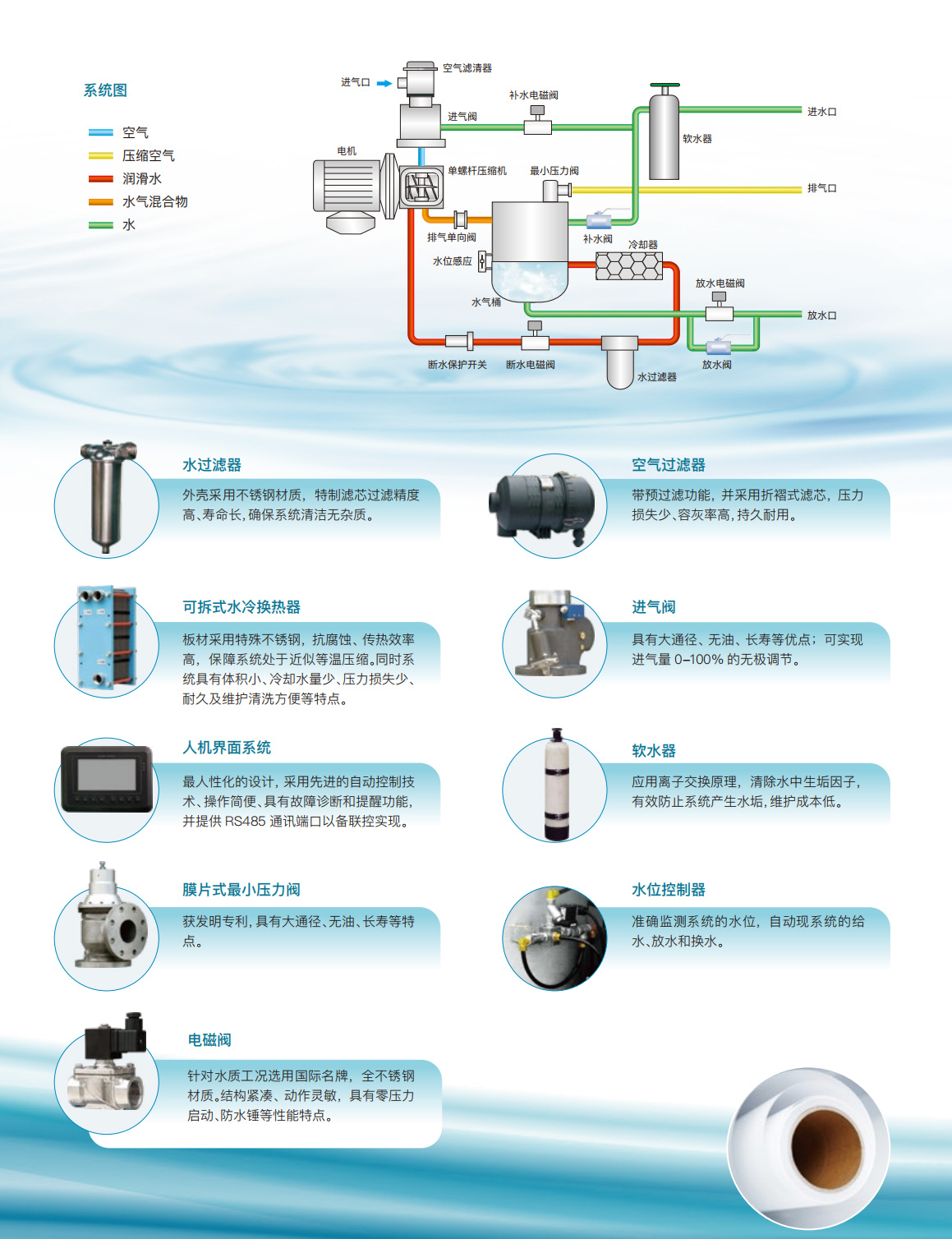

Hosts all come from water

Special material host, the application of the world's advanced sealing system, set mechanical seal, air curtain, labyrinth seal and bypass channel in one

Kaitek overcomes three major technical difficulties

• High reliability to solve the mechanical seal between the bearing and the compression chamber

• The host and the whole machine have anti-corrosion ability

• Overcome the low viscosity of water to solve the meshing gap seal

oil-free screw compressor

55~300kW

7~70m³/min

1.5~10bar

Ultra-energy-saving pure oil-free high reliability and low noise

• Single Screw

A screw and two left and right vertical arrangement of the star wheel to form two compression chamber, screw each rotation, compression 12 times.

• High reliability

The unit adopts all stainless steel host, and the host parts adopt special stainless steel with excellent wear resistance and corrosion, which is more durable than coating materials, and saves rust prevention maintenance.

• Ultra energy saving

Application of Katek's three-wire meshing, non-equal-width tooth technology and proprietary processing technology to overcome the low viscosity of water and maintain a high volume ratio. Through water spray atomization cooling, ensure that the system is approximately isothermal compression.

• Low noise

Single screw axial and radial force balance, star wheel in the water film lubrication with the screw free rotation, so the host components in low load smooth operation, to ensure low noise and durability.

•Pure oil-free

The main engine is sprayed with water for cooling and sealing, and the world's advanced sealing system is used between the compression chamber and the bearing to ensure that the entire system is oil-free.

Product Consulting

We will contact you within one working day. Please pay attention to your email.