Process gas compressor

Classification:

Key words:

- Product Description

-

Kaishan shares have independent intellectual property rights of the process screw compressor, with a professional product manufacturing system.

The dry screw compressor does not inject lubricating oil into the compression chamber during the working process, so it can provide pure, oil-free and dust-free compression medium, which is often used to compress flammable, explosive and toxic medium gas.

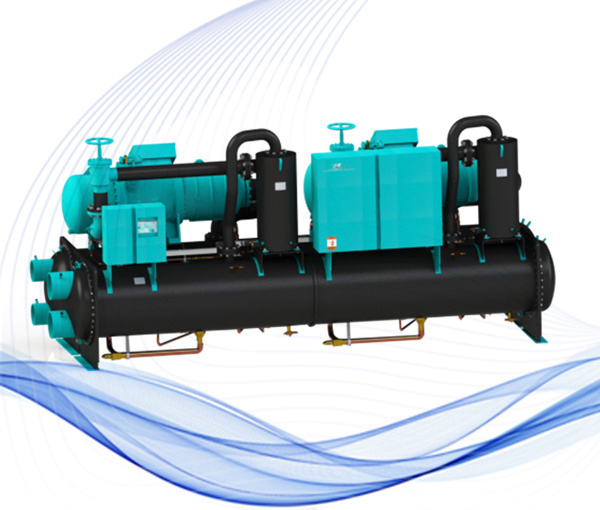

Dry screw compressor unit

Innovative Host Design:

The main machine adopts "Y" rotor type line, cylindrical and tapered roller bearing triple design, and the bearing life is more than 100,000 hours. Superb reliability and service life. Low speed large head design, stable performance, lower noise integrated design, easy installation.

Industry Applications:

• Petrochemical

• Refineries

• Chemical Plant

• Coal chemical industry, energy industry, etc.

Scope of supply:

• Suction pressure: -0.085~0.8 MPa

• Exhaust pressure: 0.15~2.0 MPa

• Exhaust volume: 10~1380 m3/min

Technical features:

• Large bearing diameter, short-to-diameter ratio, direct drive-to ensure high reliability of the unit

• Excellent rotor profile, poppet valve and optimized orifice design-significantly improve unit efficiency

• No gearbox, no rectangular seal, low tip speed, low exhaust flow rate. -Effective noise reduction

Oil-injected screw compressor unit

The Kaishan oil-injected screw compressor system has superior and reliable performance, low operating vibration, low noise, high efficiency and no wearing parts. The unique lubrication method simplifies the mechanical structure and increases the airtight function.

Scope of application:

• Petrochemical applications

• Fuel gas

• Acid hydrocarbon gas

• Hazardous gases, etc.

Scope of supply:

• Suction pressure:-0.05~0.8 MPa

• Exhaust pressure: 0.2~4.0 MPa

• Exhaust volume: 2.2~150 m3/min

Technical features:

• Customized orifice, variable content ratio, auto-match back pressure-reduce power consumption, improve efficiency

• Modular design, fully skid-mounted layout-compact structure, easy to deploy quickly

• Complete integrated electrical and control system, Internet-based remote monitoring-easy to manage

Type of gas treated:

Coke oven gas, coal mine gas, natural gas, coalbed methane, biogas, ethylene, styrene, blast furnace gas, butadiene, acidic hydrocarbons, steam recovery, water vapor, decomposition gas, nitrogen, acetylene, lime kiln gas, hydrogen, carbon dioxide, Torch gas, ethane, propylene, propane, ammonia, chlorine, carbon monoxide, visbreaking furnace emission gas, refrigerant, fuel gas, helium, hydrocarbon mixture, butane, methane, acid gas other gases.

Product Consulting

We will contact you within one working day. Please pay attention to your email.